Hyundai and Kia are using our TPE solution MEGOL™ DP2334/70FL1 UVR1 BLACK to produce interior and exterior fixed glass sealings for the 4-door sports sedan Kia K8 (Kia Stinger). The collaboration started for quarter glass seals and mirror triangle sealings thanks to the support and competence of our Korean distributor Novachem. Subsequently, Trinseo and Novachem were able to expand the business to fixed glass sealings because of our material’s high performance and its cost-competitiveness.

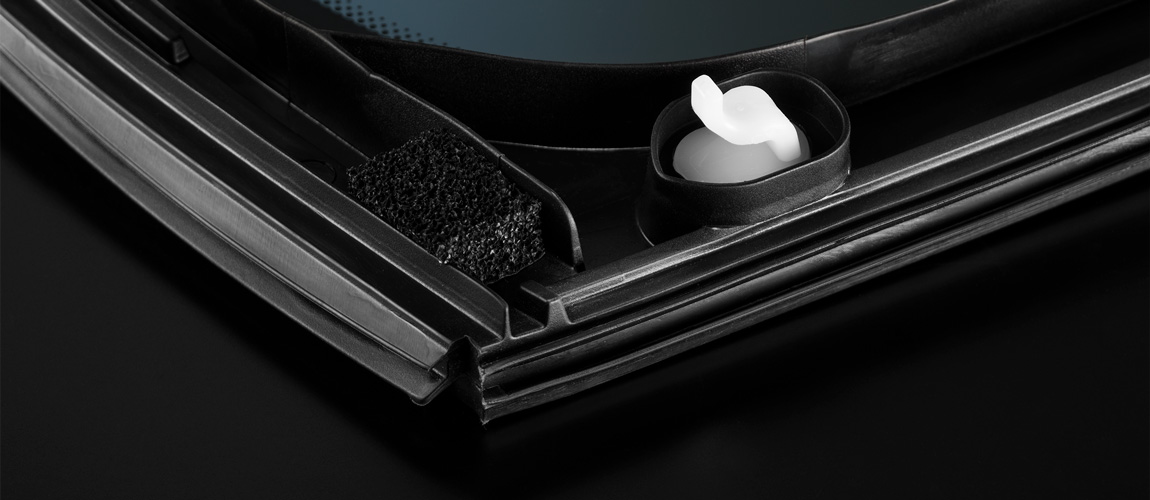

In an ever-evolving market for automotive glazing, OEMs and suppliers must meet consistently increasing customer demands. Glass applications play a vital role in the aerodynamics, aesthetics, and comfort of a vehicle. Today's automotive glazing fulfills many complex tasks, such as active and passive safety functions, or the integral contribution to the stability of the bodywork (structure-bonded fixed glazing). The demands of tier 1 supplier Sejin and the OEMs on the TPE solution to be used for the quarter and fixed glass application in our project were correspondingly high.

Hyundai/Kia required a material enabling optimum cohesive adhesion of the TPE soft seal onto PC/ABS and ASA rigid frame in an overmolding application with two components. Since the final parts are used for exterior as well as for interior sealings, compliance with industry standards for exterior weathering resistance was expected. Above all, the material had to offer good processability in combination with a very good surface without sink marks or flow lines, as well as cost-effective, very short cycle times. The TPE solution had to work smoothly in various molds with different geometries.

MEGOL™ DP2334/70FL1 UVR1 BLACK was the perfect match for the challenging requirements, and its price advantage over the competition determined the success of our project. The material meets the Hyundai/Kia material specification MS 210-06 for molded plastics used in general performance of automotive exterior parts.

Our successful TPS-SEBS Compound provides a peeling force greater than or equal to 7N/mm (according VDI 2019 standard), enabling the required cohesive adhesion with the rigid frame made from PC/ABS. At the same time, MEGOL™ DP2334/70FL1 UVR1 BLACK successfully passed the Hyundai/Kia climatic tests. It meets both the requirements of exterior weathering resistance (2500 kJ/sq m exposure with ΔE < 3 as well as the requirements for interior use (e. g. fogging, VOC emissions and odor).

The customer benefits from easy demolding and from the wide processing window. The flow properties offer great flexibility even with complex geometries. It is currently used in eight molds for eight different parts. The material's good surface appearance and processability allow for a 5-second short cycle time.

MEGOL™ DP2334/70FL1 UVR1 BLACK can be considered a material of choice for 2K exterior (and interior) applications on PC/ABS and ASA, where high performance and versatility are required and need to be accompanied by a significant price competitiveness without a lack of quality.

Download a brochure highlighting Trinseo TPE solutions and automotive applications (available in English and Chinese).