Low odor is a crucial property in automotive design. That the feature is as important for exteriors and semi-structural parts as for interior elements of a vehicle is demonstrated by this challenge that we solved for Fiat Chrysler Automobiles (FCA).

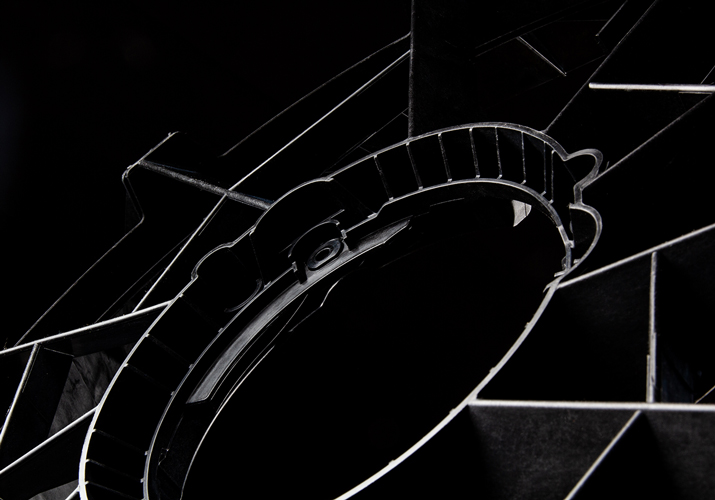

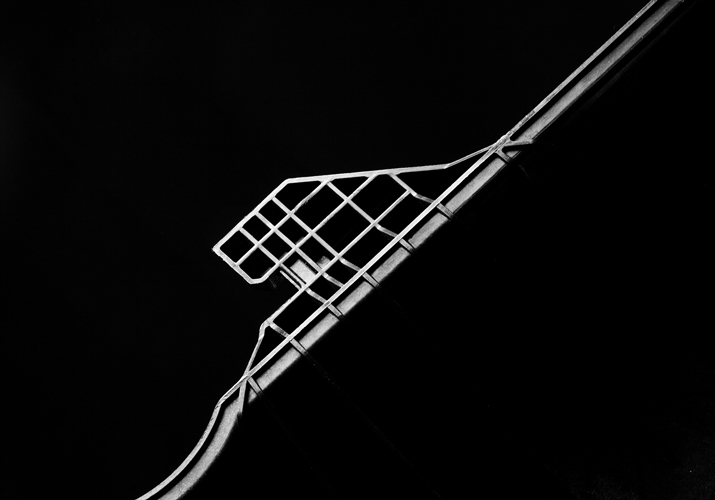

The OEM was confronted with an odor issue on their Ram platform, which includes popular heavy trucks such as the Ram 1500 and the Jeep Grand Cherokee. The source of the strong odor turned out to be the fan shroud, which was molded by Shape Corp for Brose using a material by a Trinseo competitor. Unfortunately, the quality of the part did not live up to the company’s or their customers’ standards. Buyers noticed a foul odor and quickly started to get the fan shroud replaced as a warranty repair at the dealership. So, FCA went searching for an alternative plastic material – and consulted Trinseo.

Fiat Chrysler Automobiles requested a sample of Trinseo’s INSPIRE™ PP LGF 9621 and ENLITE™ PP LGF 7900 concentrate pellets. Our family of INSPIRE™ Polypropylene blending solutions and the system of ENLITE™ Polypropylene Long Glass Fiber offer a variety of properties that suit the fan shroud application, such as thin wall thickness, robustness and a low odor level. Shape Corp ran trials and conducted an SAE odor rating test in order to compare our products to the competitor’s material.

Shape Corp molded the parts with the Trinseo material and the outcome was positive: The parts molded well and offered good dimensional stability so they were provided to Brose. Brose tested the parts for vibration, flex, and air displacement along with final dimensional checks. The Trinseo material combination of 50% INSPIRE™ PP LGF 9621 and 50% ENLITE™ PP LGF 7900, resulting in a 30% PP LGF molded part, passed all required tests and was particularly convincing due to its low odor qualities. Thanks to these results, FCA quickly switched to our material.

Due to the precise properties of our products, we were able to help Fiat Chrysler Automobiles and make the fabrication of the part more efficient and more pleasant for them, their manufacturers and end-customers. We were especially pleased when we were notified that by switching to our product the molder could also record a removal of the odor during manufacturing.

This case gave us the opportunity to reach new positive exposure at OEM Fiat Chrysler Automobiles, tier Brose, and molder Shape Corp.